Minichamps Diecast vs Resin: Top 5 Differences

The world of model car collecting offers a fascinating array of choices, with Minichamps being a highly respected name in the industry. When it comes to selecting a Minichamps model, one of the key decisions collectors face is whether to opt for a diecast or a resin model. Both materials offer unique characteristics that appeal to different collectors. Understanding the key distinctions between diecast and resin will help you make an informed choice, allowing you to enhance your collection with models that perfectly match your preferences. This guide will highlight the top 5 differences between Minichamps diecast and resin models, helping you navigate the world of scale model cars.

Material Composition

The most fundamental difference lies in the materials used for construction. Diecast models are primarily made from a metal alloy, typically zinc alloy, which is injected into molds under high pressure. This process allows for intricate detailing and a solid, substantial feel. Resin models, on the other hand, are crafted from a synthetic resin material. This liquid resin is poured into molds and then cured, resulting in a model that can offer incredible detail due to the precision of the molding process. The material choice significantly impacts other aspects, such as weight, detail, and ultimately, the overall experience of owning the model.

Diecast Material

Diecast models use a metal alloy, often a combination of zinc, aluminum, and sometimes other metals. This composition provides durability and a satisfying weight, contributing to the model’s premium feel. The use of metal also allows for a degree of heat resistance, which is crucial during the manufacturing process. The metal alloy is injected into molds under high pressure, a process that ensures the fine details are captured, resulting in accurate representations of the original vehicles. This material choice is a cornerstone of the diecast models, ensuring a robust and realistic feel that many collectors appreciate. Image of diecast metal composition.

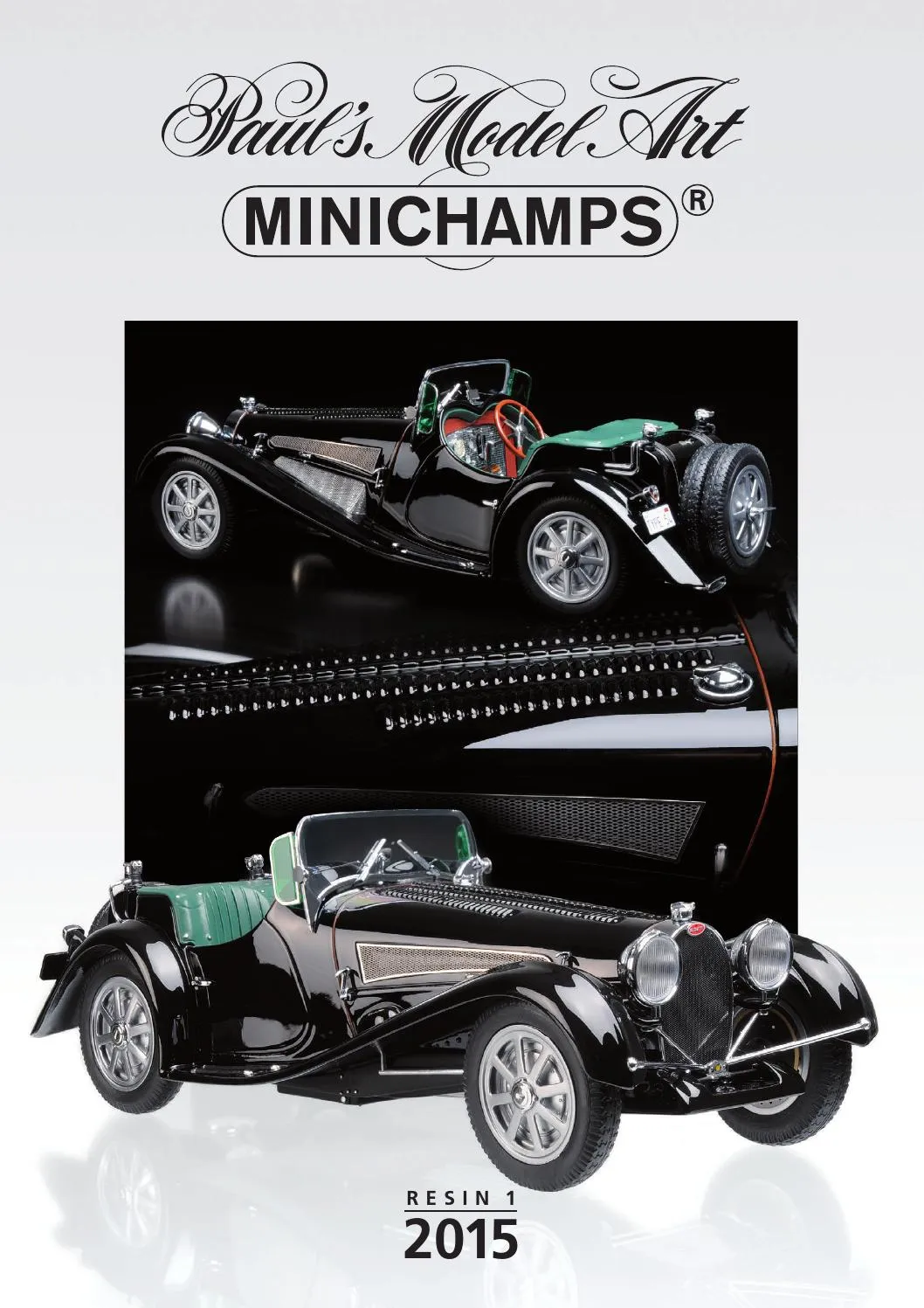

Resin Material

Resin models are constructed from a synthetic resin, a liquid material that hardens after being poured into molds and cured. This process enables manufacturers to create models with extremely fine details, often surpassing those found in diecast models. The resin can capture intricate shapes and delicate features that might be challenging to reproduce in metal. The material itself is lighter than diecast, which can contribute to a different feel in hand. This allows for advanced detailing, and the use of resin is especially common for limited-edition models that are meant to showcase high levels of craftsmanship. Image of resin model car details.

Weight and Feel

The weight and tactile feel of a model are essential aspects of the collecting experience. Diecast models are typically heavier due to the metal alloy used in their construction. This weight contributes to a sense of quality and realism, making the model feel more substantial and authentic in hand. The weight also affects how the model sits on a shelf, providing a grounded and stable presence. Resin models are generally lighter, which offers a different experience. The difference in weight, while not always dramatic, can be noticeable, influencing the overall perceived value and the collector’s sensory engagement with the model. Image of minichamps model comparison.

Diecast Weight and Feel

The weight of diecast models is a significant factor for many collectors. The solid, dense feel provides a sense of quality and durability. When held, a diecast model feels substantial, adding to the perceived value and realism. This weight also helps the model to remain stable on display, adding to its overall presentation. This weighty feel is a characteristic that many enthusiasts associate with high-quality model cars and can contribute to a more immersive collecting experience.

Resin Weight and Feel

Resin models, being lighter, offer a different tactile experience. While they may not have the same heft as diecast models, they can still feel high-quality due to the precise detailing often found in resin models. The lighter weight can make them easier to handle, and the smooth, often polished finish of the resin provides a distinct feel. The lighter weight can also be beneficial in terms of display, making it easier to manage multiple models. It’s a matter of preference whether a collector favors the heavier, more grounded feel of diecast or the lighter, more delicate feel of resin.

Detail and Accuracy

Both diecast and resin models strive for high levels of detail, but the manufacturing processes and materials can result in differing levels of precision. Resin models often excel in capturing the most intricate details due to the molding process. However, the manufacturing process and the ability to achieve fine details is highly dependent on the tooling and processes used by the manufacturer. While diecast models can also achieve impressive levels of detail, the characteristics of the metal alloy can sometimes present challenges in replicating the most delicate features. The ultimate goal is to create a model that accurately represents the original vehicle, and both diecast and resin have their strengths in achieving this goal.

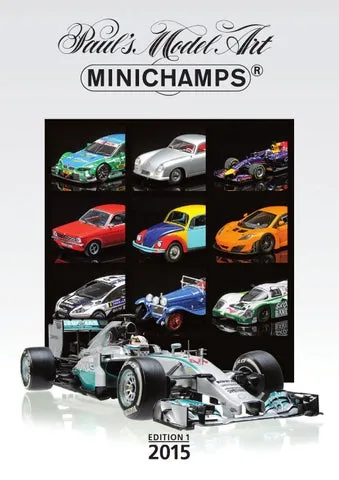

Diecast Detail

Diecast models benefit from the high-pressure injection molding process, which allows for a good level of detail. The metal alloy captures the contours and features of the original vehicle with impressive accuracy. However, the metal can sometimes limit the level of detail achievable compared to resin. Diecast models often feature functional elements, such as opening doors and hoods, which contribute to their appeal. The overall focus in diecast is on providing a balance of detail, durability, and functionality, creating models that are both visually appealing and enjoyable to handle. Image of minichamps diecast models.

Resin Detail

Resin models are known for their exceptional level of detail, thanks to the precision of the molding process. The resin can capture the most intricate features, such as delicate grilles, fine lines, and complex interior details. Resin models frequently showcase advanced detailing, and the manufacturing methods often allow for a more seamless construction. This level of detail makes resin models highly sought-after by collectors who prioritize accuracy and realism. The focus on minute detailing sets resin models apart, making them a premium option for collectors seeking the ultimate in model car fidelity. Image of minichamps resin models.

Production and Availability

The production process and availability of diecast and resin models can differ significantly. Diecast models, owing to the nature of their manufacturing process, are often produced in larger quantities. This can make them more readily available and accessible to a broader range of collectors. Resin models are often produced in limited quantities, which can contribute to their exclusivity and higher prices. The availability of certain models can also vary depending on the manufacturer, the model’s popularity, and the overall demand within the collecting community. Understanding these factors is essential for collectors who are seeking specific models for their collections.

Diecast Production

Diecast models generally have a more streamlined production process, allowing manufacturers to produce larger quantities. The high-pressure injection molding process is efficient for mass production, making diecast models more accessible to a wider audience. The ability to produce in greater numbers often translates to a wider distribution network, increasing the chances of finding a desired model. This higher production volume often results in a more consistent supply, allowing collectors to acquire their favorite models more easily. Image of minichamps manufacturing process.

Resin Production

Resin models are typically produced in smaller batches. The resin casting process is more labor-intensive, which contributes to the limited production runs. This limited availability often leads to higher prices and increased collectibility. Many resin models are released as limited editions, adding to their exclusivity and desirability. Collectors need to be more proactive in acquiring resin models, as they often sell out quickly. The rarity of resin models often contributes to their value, making them prized possessions within a collection.

Price Point

The price of Minichamps diecast and resin models varies significantly, reflecting the materials used, the level of detail, the production process, and the model’s overall rarity. Diecast models, due to their more accessible production process, are usually more affordable, making them a popular choice for collectors of all budgets. Resin models, often being more detailed and produced in limited quantities, typically command higher prices, which reflects their exclusivity and the greater level of craftsmanship involved. Understanding the price differences is crucial when making purchasing decisions, and balancing budget with collecting goals is a fundamental part of building a collection. The price can also fluctuate based on the demand for a specific model and its overall condition.

Diecast Pricing

Diecast models are generally priced more affordably. The materials and production methods are more cost-effective, allowing manufacturers to offer models at a lower price point. This makes diecast models a good entry point for new collectors and allows experienced collectors to expand their collections without breaking the bank. The lower price point also means it’s easier to acquire multiple models without exceeding a budget. Diecast models provide excellent value for the price, offering a great balance between quality, detail, and affordability. Image of minichamps model shelf.

Resin Pricing

Resin models are typically priced higher due to the materials and manufacturing processes. The intricate detailing, the limited production runs, and the craftsmanship involved all contribute to the higher price. Resin models are often considered premium items, reflecting their exclusivity and their appeal to serious collectors. While the initial investment may be higher, resin models can be a good investment and often retain their value over time, especially limited-edition models. Collectors who value exceptional detail and rarity are often willing to pay the premium for a resin model.

In conclusion, the choice between Minichamps diecast and resin models depends on individual preferences and collecting goals. Diecast models offer a good balance of detail, durability, and affordability, while resin models excel in detail and exclusivity. Consider the material, weight, level of detail, production volume, and price when making your selection. Both options provide fantastic opportunities for building an impressive collection. Image of minichamps diecast models.